How to choose the right packaging solution for the beer industry, daily chemical enterprises, beverage enterprises and medical enterprises?

Новости Cratusfilm. Глава вторая: Как выбрать правильное упаковочное решение для вашей пивоваренной промышленности, предприятий по производству бытовой химии, предприятий по производству напитков и медицинских предприятий

Noticias de Cratusfilm, Capítulo Dos: Cómo elegir la solución de envasado adecuada para su empresa cervecera, empresa química, empresa de bebidas y empresa médica.

The shrink film family includes PE shrink film, PETG shrink film, PVC shrink film, OPS shrink film, PLA shrink film, and POF shrink film.

As an efficient and convenient packaging solution, PE shrink film is widely used in product packaging across various industries. Specifically, it excels in alcohol packaging by tightly adhering to bottle surfaces to ensure transport safety. For canned beverages, PE shrink film effectively secures can bodies to prevent collisions and friction. In mineral water products, its superior sealing performance guarantees fresh and pure water quality. Additionally, PE shrink film is extensively applied in packaging for carbonated drinks, fruit juices, and dairy products, providing reliable protection throughout the supply chain. Furthermore, textile products often utilize PE shrink film for whole-piece packaging to prevent contamination and damage during storage and transportation.

The product’s widespread popularity stems from its exceptional physical properties. First, PE shrink film demonstrates remarkable flexibility, allowing it to conform to various product shapes while ensuring a secure and aesthetically pleasing seal. Second, it exhibits outstanding impact resistance, effectively protecting contents even during intense transportation vibrations. Third, the film’s exceptional tear resistance minimizes damage during handling, significantly enhancing packaging reliability. Additionally, this moisture-resistant material maintains stable performance in humid environments without deformation or failure. Finally, PE shrink film’s high shrinkage rate enables tight sealing when heated, further improving packaging integrity and ensuring optimal protection throughout the product lifecycle.

PVC shrink film has become a difficult-to-manage waste, causing certain environmental impacts. Therefore, despite its significant advantages in transparency, gloss, and shrinkage rate, its non-recyclable nature still requires attention.

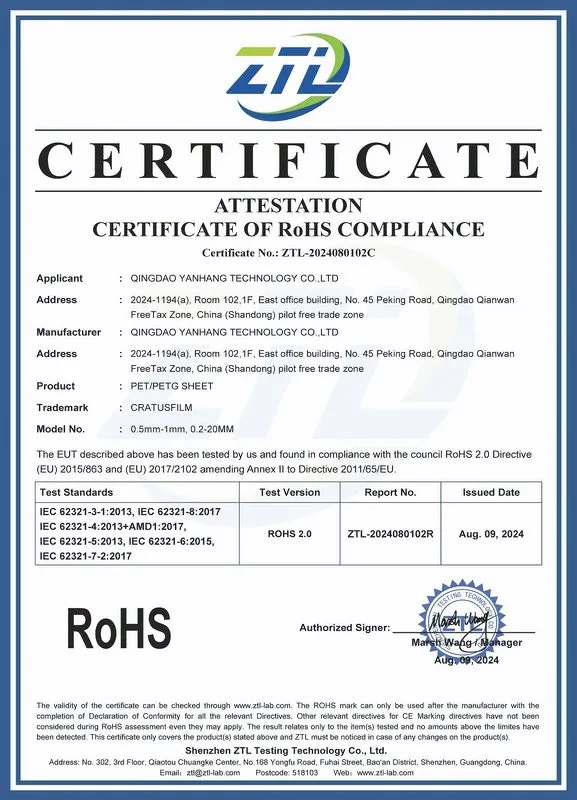

PETG boasts superior shrinkage control, high transparency, glossy finish, low haze, excellent printability, high strength, and excellent heat sealing properties. Its low natural shrinkage during storage makes it ideal for sleeve labeling, gravure, flexographic, offset, and digital printing. Compatible with steam, hot air, or infrared shrink tunneling, it allows flexible customization of product thickness and shrinkage rate (0.015~0.06mm 35%~85%) to meet customer requirements.

POF shrink film features high gloss, excellent toughness, strong tear resistance, and uniform heat shrinkage, making it ideal for fully automatic high-speed packaging machines.

PLA biodegradable shrink film naturally decomposes in the environment through microbial action in soil and water, along with ultraviolet radiation from sunlight. The resulting materials are widely used in packaging films, shrink films, shopping bags, and garbage bags, playing a positive role in environmental protection.