When sourcing PETG shrink film, many buyers focus mainly on price and basic specifications. However, quality consistency is what truly determines whether shrink sleeve production runs smoothly or becomes a source of defects and waste.

This article explains the key quality standards and checkpoints industrial buyers should verify before placing bulk orders of PETG shrink film.

1. Thickness Consistency & Tolerance

Film thickness consistency is one of the most critical quality indicators.

Even small thickness variations can cause:

-

Uneven shrinkage

-

Wrinkles after shrinking

-

Cracking or splitting during application

What buyers should check:

-

Nominal thickness (e.g. 40μm)

-

Thickness tolerance (recommended: ±5% or better)

-

Cross-web thickness uniformity

Low-cost PETG shrink film often fails in this area, leading to unstable production.

2. Shrink Ratio Stability

Datasheets alone are not enough. What matters is shrink ratio stability from roll to roll.

Typical PETG shrink film values:

-

TD shrink: 65%–75%

-

MD shrink: 0–5%

Quality risk:

Inconsistent shrink performance can cause sleeve distortion, label misalignment, and poor appearance on the shelf.

Buyer tip:

Always request actual shrink test results under real tunnel conditions.

3. Shrink Uniformity & Smoothness

High-quality PETG shrink film shrinks evenly and smoothly, especially on complex bottle shapes.

Poor-quality material may show:

-

Localized wrinkles

-

Uneven tension zones

-

Shrink marks around curves or neck areas

Uniform shrink behavior is essential for:

-

Full-body shrink sleeves

-

Bottles with curves, handles, or transitions

4. Printing Performance & Ink Adhesion

Most PETG shrink film is used for printed shrink sleeves, making printing quality a major standard.

Key points to verify:

-

Compatibility with gravure or flexographic printing

-

Ink adhesion performance

-

Resistance to ink cracking after shrinking

High-quality PETG film ensures:

-

Stable ink anchoring

-

Minimal image distortion

-

Clean, sharp graphics after shrink

5. Mechanical Strength & Toughness

Mechanical properties directly affect performance on high-speed sleeve applicators.

Buyers should check:

-

Tensile strength

-

Elongation at break

-

Tear resistance

Compared with OPS, PETG shrink film offers better toughness, reducing:

-

Sleeve tearing

-

Breakage during transportation

-

Downtime on production lines

6. Roll Quality & Winding Control

Even with good raw material, poor roll quality can cause serious application problems.

Inspect:

-

Flatness of the film

-

Uniform winding tension

-

Clean and straight edges

-

No blocking or telescoping

Good roll quality ensures smooth feeding and stable operation on automatic equipment.

7. Cleanliness & Defect Control

Industrial buyers should confirm that PETG shrink film is free from:

-

Gels

-

Black spots

-

Surface contamination

-

Scratches

These defects can directly affect printing quality and final appearance.

8. Storage Stability & Shelf Life

Quality PETG shrink film should maintain performance during storage.

Standard expectations:

-

Shelf life: up to 12 months under proper conditions

-

No premature shrinkage

-

No loss of dimensional stability

Proper packaging and moisture protection are especially important for export shipments.

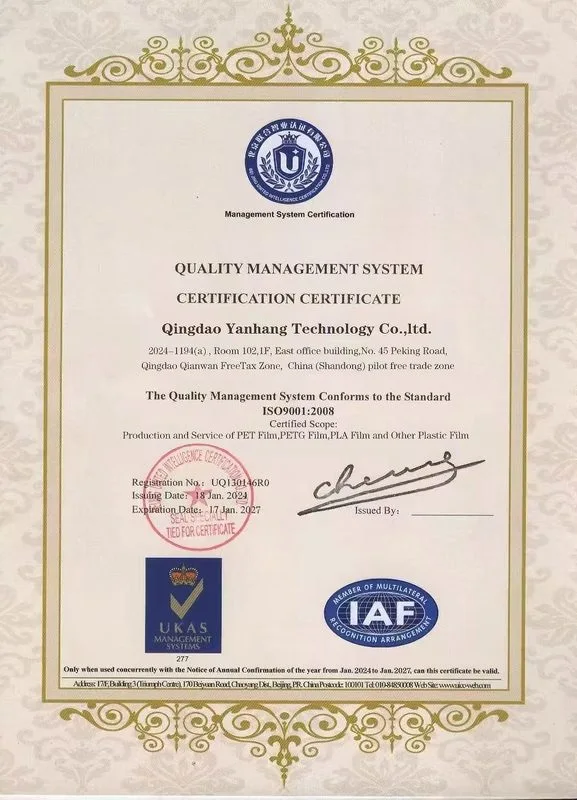

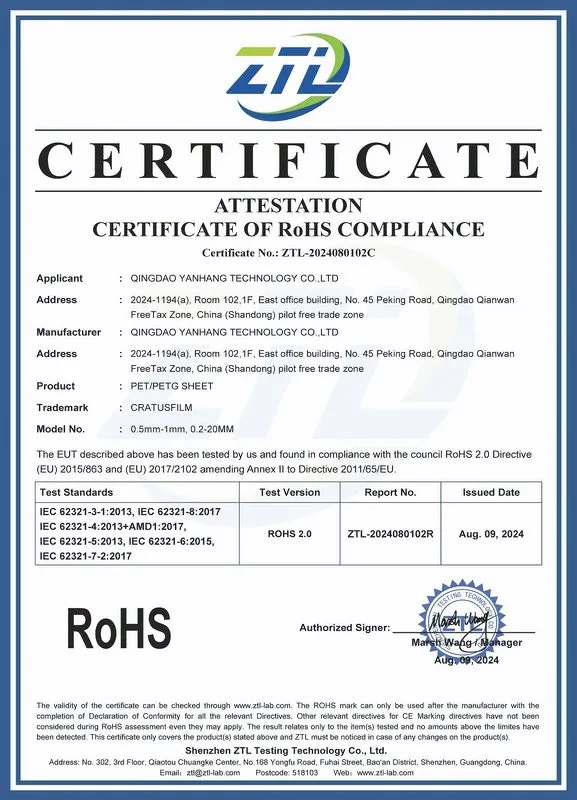

9. Supplier Quality Assurance System

Finally, quality standards depend heavily on the supplier.

Buyers should confirm:

-

Consistent production processes

-

Quality inspection records

-

Sample testing before mass production

-

Export experience and technical support

A reliable supplier helps buyers reduce long-term risk, not just initial cost.

Conclusion

PETG shrink film quality is defined by consistency, stability, and process reliability — not just basic specifications.

By verifying thickness tolerance, shrink stability, printing performance, and roll quality, buyers can significantly reduce production defects and improve overall packaging efficiency.