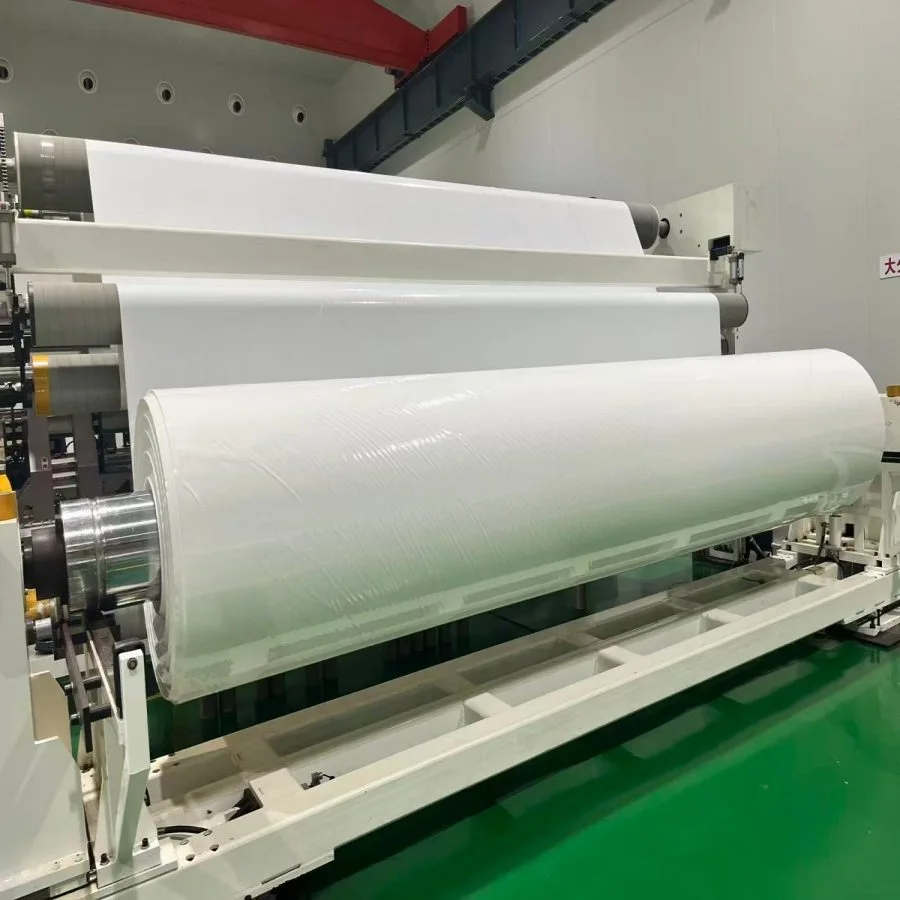

White PETG Shrink Film

White PETG shrink film core advantages include:

-Optical and shielding performance

The milky white tone provides a soft shading effect, effectively blocking ultraviolet rays and protecting light sensitive products (such as food and cosmetics) from oxidation and deterioration, while creating a high-end visual texture.

-Mechanical and Environmental Characteristics

Inheriting PETG’s high impact resistance (3-10 times that of modified polyacrylic esters) and excellent flexibility, suitable for complex container packaging; The material is recyclable and meets FDA food contact standards and EU RoHS environmental certification

-Application adaptability

Extending shelf life through light shielding in food packaging, balancing brand display and product protection in the daily chemical industry. Its printing performance supports 360 degree full-color label design, enhancing shelf attractiveness

PETG shrink film is widely used in various packaging applications due to its excellent clarity, high shrinkage rate, and recyclability. It is commonly applied in the food and beverage industry for bottle labeling and packaging, ensuring product safety and visual appeal. Additionally, it serves the electronics, cosmetics, and pharmaceutical sectors, providing protection and branding opportunities. Its eco-friendly properties make it a preferred alternative to traditional PVC films, aligning with global sustainability trends. The material’s versatility and compliance with food-grade standards further enhance its market adoption.

1.It offers highly controllable shrinkage, high transparency, high gloss, low haze, excellent printability, high strength, excellent heat sealing properties, and low natural shrinkage during storage.

2.It is suitable for sleeve labeling, gravure printing, flexographic printing, offset printing, and digital printing; and is compatible with labeling methods using steam, hot air, or infrared shrink tunnels.

3.Variety of products available to meet customer needs: thickness: 0.015-0.06mm, shrinkage: 35%-78%.

Technical Data Sheet:

| Property | Unit | Typical Value | Test Method | |

| Thickness | Micron | 30-50 | ASTM D374 | |

| Tensile Strength | MD | Mpa | ≥45 | ASTM D882 |

| TD | ≥200 | |||

| Elongation At Break | MD | % | ≥400 | ASTM D882 |

| TD | ≥35 | |||

| Heat Shrinkage | 70℃ TD | % | 25 | 10sec/water |

| 80℃ TD | 58 | |||

| 90℃ TD | 70 | |||

| 100℃ TD | 75-78 | |||

————Why Choose Us————

| 01/Our Company

CRATUSS FILM offers high-quality flexible packaging products at fair prices. We manufacture in Shandong and Anhui, China, as well as in Sri Lanka and other locations.

|

03/Customer Service

Service We provide excellent after-sales support, tracking product usage, and gathering positive feedback. Our team responds quickly, usually within 24 hours. |

| 02/ Applications

Our films, includingPETG, PVC, OPS,POF,PEshrink films, are suitable for a variety of uses. They can be used for packaging, shrink labels, medical applications, electrical insulation, wrappingand industrial purposes. |

04/Fast Delivery

We maintain a full stock of products and can deliver quickly. We offer many styles for you to choose from. |

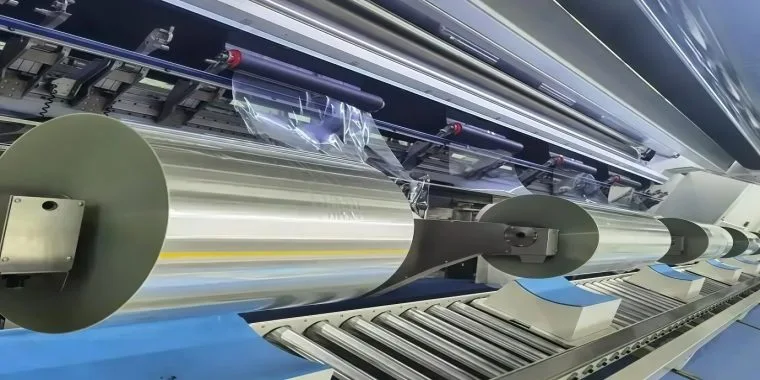

Factory Strength: